Robello Samuel, Chief Technical Advisor and Halliburton Fellow (Well Engg.), Halliburton

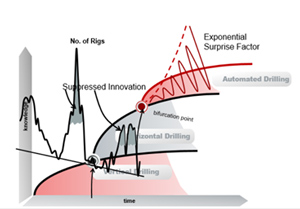

Robello Samuel, Chief Technical Advisor and Halliburton Fellow (Well Engg.), HalliburtonThe digital transformation is providing impetus in the advancements in the oil and gas industry. Figure1 shows technological advancements through time. The bifurcation points offer the fusion of new technologies during the industry contraction mode, which translates the environment similar to the industrial revolution. As the industry moves toward automated drilling systems, not only comprehensive 3600 engineering optimization has become very critical, but also the fusion of data analytics at the edge into the system has become increasingly essential. Even though it may sound like a futurist’s pipe dream, the exponential technologies in other industries will provide impetus in accelerating the realization of such a system. With so many technologies advancing at the same time around us, it is up to us to create the layered evolution of an advisory system to rig controls and position ourselves for the final automation—that even if the driller is on the rig floor, auto driller should take it beyond the conditional automation and drill autonomously. It is not just drilling ahead but with data, ML, AI, automation, and people converging to autonomics making the physical drilling system in a self-configuring, self-diagnosis, self-healing, self-optimizing, and self-managing state. The drilling world is on the path to reverse-engineering the brain, and the computer architecture mimicking the driller’s brain’s network. It consists of engineering formalism plus the interpretation of data, thus providing the reaction link between the mathematical formulation and elements of the physical world. The engineering algorithms and connectivity to the exponential technologies have to be seamless and in constant contact with the physical system all the time, anywhere, and everywhere. The other technologies that are handholding are cyber-physical systems, real-time embedded systems, deep Neural Networks and Reinforcement learning, distributed public ledger (blockchain technologies), IOT, IIOT, sensors, cloud computing, digital twins, edge computing and cloud communication, timed models and stream analytics, and hybrid systems–AI/ML/Physics.

Cyber-physical systems (CPSs) integrate cyber capabilities (computation, communication, and control) with physical capabilities (systems governed by the laws of physics and operating in continuous time and other physical processes). Both are tightly coupled and engineered to enhance performance at all disciplines of petroleum engineering. Even though the technologies behind cloud computing existed before the present computing power, communication with the sensors, cost per computation, fault-tolerant computation in real-time, and web services provide elastic support and scalability to visualize and take actions in near real-time.

Cyber-physical systems (CPSs) integrate cyber capabilities (computation, communication, and control) with physical capabilities (systems governed by the laws of physics and operating in continuous time and other physical processes). Both are tightly coupled and engineered to enhance performance at all disciplines of petroleum engineering. Even though the technologies behind cloud computing existed before the present computing power, communication with the sensors, cost per computation, fault-tolerant computation in real-time, and web services provide elastic support and scalability to visualize and take actions in near real-time.

"Eventually, the rise of machines and intelligence will lead to settling the debate of drilling engineer versus machine as the oil and gas industry is ripe for transformation"

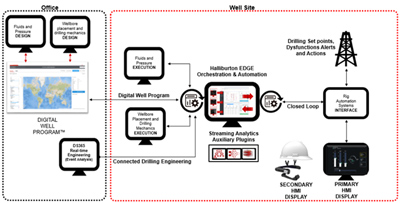

Since there are several uncertainties, a downhole hybrid approach is used, i.e., physics-informed or guided data analytics have to be done in the cloud to describe the process better. The problem encountered is the penalty of computational time when these engineering models are coupled. Surrogates and proxies have to be created instead of calling the engineering calculations every time to prescribe and predict what is going to happen for the automated system. Under these conditions, the hybrid model provides better solutions. This creates information fusion with different levels of uncertainty. This way,  paradoxes are suppressed, uncertainties are neutralized, and the engineering principles are not violated. The stream-processing frameworks on the cloud provide the capability to process, analyze, and provide solutions at a much faster rate to office and other control centers. Additionally, the resource elasticity is provided by the use of various transient engineering calculations such as fluid mechanics, solid mechanics, and solvers in the form of ultrafast micro-services. Based on this approach, the proxy engineering models are created, and further, they are used with the information from the data using machine learning. To prevent additional computing time, blockchain can be used to find out the pending events or transactions. Non-blockchain events can also be added in the streaming paths. The programs which used to run explicitly are executed headless and provide the capacity to withstand dynamic data workloads. This helps to not only interpolate but also extrapolate as the data are processed. Based on this approach, the events are predicted and the digital programs are updated with the engineering models and data at rest but in motion. This allows checking the change in the status by running engineering calculations in real-time based on the real-time status change. Figure 2 shows the workflow using cloud computing and it results in intelligent automation paired with Richer Well Construction 4.0 (With Data & Digital Twin).

paradoxes are suppressed, uncertainties are neutralized, and the engineering principles are not violated. The stream-processing frameworks on the cloud provide the capability to process, analyze, and provide solutions at a much faster rate to office and other control centers. Additionally, the resource elasticity is provided by the use of various transient engineering calculations such as fluid mechanics, solid mechanics, and solvers in the form of ultrafast micro-services. Based on this approach, the proxy engineering models are created, and further, they are used with the information from the data using machine learning. To prevent additional computing time, blockchain can be used to find out the pending events or transactions. Non-blockchain events can also be added in the streaming paths. The programs which used to run explicitly are executed headless and provide the capacity to withstand dynamic data workloads. This helps to not only interpolate but also extrapolate as the data are processed. Based on this approach, the events are predicted and the digital programs are updated with the engineering models and data at rest but in motion. This allows checking the change in the status by running engineering calculations in real-time based on the real-time status change. Figure 2 shows the workflow using cloud computing and it results in intelligent automation paired with Richer Well Construction 4.0 (With Data & Digital Twin).

Eventually, the rise of machines and intelligence will lead to settling the debate of drilling engineer versus machine as the oil and gas industry is ripe for transformation.